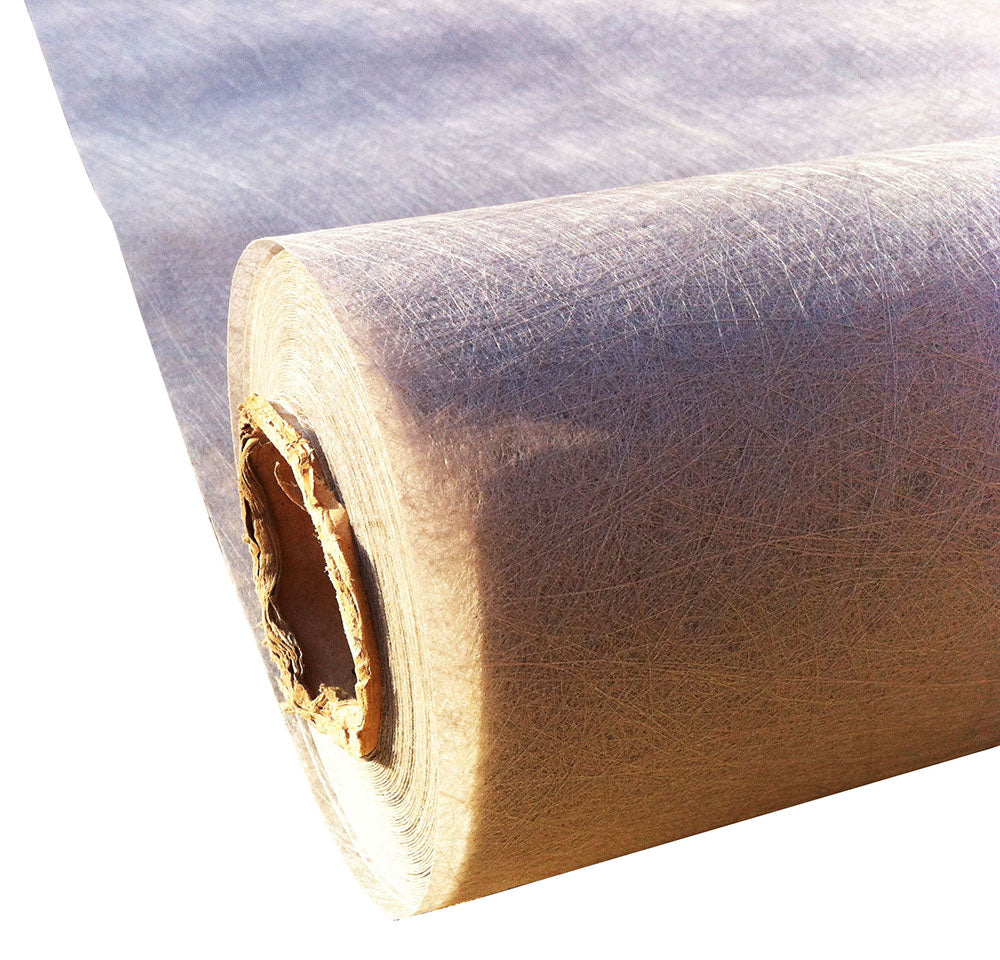

Description

Terram T1000 non-woven geotextile membrane is ideal for material separation in a variety of construction applications. Typical uses for Terram are for ground stabilisation by preventing the intermixing of the different material particles within the sub-base and subgrade. This reduces problems with surface distortion such as cracking or rutting. The 100% polypropylene fabric has a high tensile strength, yet still permits water to pass through. Because Terram is a nonwoven geotextile material, it's high strength is not limited to one direction.

Please contact a member of the team to arrange delivery, *your order may be delivered as 2 units of 2.25 x 100m rolls.

Features

- Spreading aggregates over soft areas.

- Minimises and reduce the need for excavation and replacement of the original ground.

- Stop soil particles from passing through.

- Allows work to continue during bad weather.

Application

- Construction of gravel driveways and walkways.

- Road and pavement construction.

- Car parks and hardstanding areas.

- Separating stone layers.

- Under block paving.

- Beneath turf block pavers to prevent the rootzone intermixing with sub-base.

- Under plastic paving grid installations.

- Play areas, including sandpits and under safety mulch.

- Green roofs and Sustainable Urban Drainage Systems (SUDS).

Technical Specifications

| Properties | Mean Value |

|---|---|

| Dimensions | 4.5 m x 100 m = 450 m2 |

| Weight Per Unit | 60 kg (nominal) |

| Thickness at 2kPa | 1.1 mm |

| Tensile Strength | 8.0 kN/m |

| Puncture Resistance | 1500 N |

| Cone Drop | 38 mm |

| Pore Size | 75 μm |

| Permeability | 90 l/m2s |

Terram T 1000 geotextile is recommended for use in situations where the subgrade is 1-4 % and the maximum stone size is < 70 mm. Before installation of Terram, the ground should be levelled and larger objects such as stones and roots removed.

For further information on Terram Geotextile Membrane, please contact a member of our technical sales team on 01952 897917.

For further information on Terram T1000 Non-Woven Geotextile, please speak to a member of our technical sales team on 01952 641949.

Delivery & Returns

Any applicable delivery charges will be calculated at checkout. Certain products qualify for next working day delivery if ordered before 1pm, excluding bank holidays and the festive season. Please be aware that deliveries to remote areas, including the Highlands and Cornwall, may take longer. Additional charges apply for non-mainland locations — please contact the office for further details, or you can learn more about our delivery options here.

A signature is required upon delivery. If no one is available, you can leave a signed note for the driver requesting the parcel be left in a secure location without a signature. However, please be aware that this is done at your own risk and is subject to the driver's discretion.

For large orders, please be aware that if you require a smaller 7.5 tonne lorry, the maximum weight for pallets is 750kg - otherwise the standard pallet size limit of 1000kg applies.

Please note:

- For deliveries that require a pallet, the pallet/packaging itself is the customer's responsibility and will not be uplifted or taken upon delivery.

- Deliveries are kerb side only.

- It is possible a pallet order can be delivered on a vehicle up to the size of a 26T lorry.

If you have any access restrictions for lorries or large vehicles, please speak to our sales team on 01952 641949.

Collection from our Telford, Shropshire, Trade Counter is available for this product.